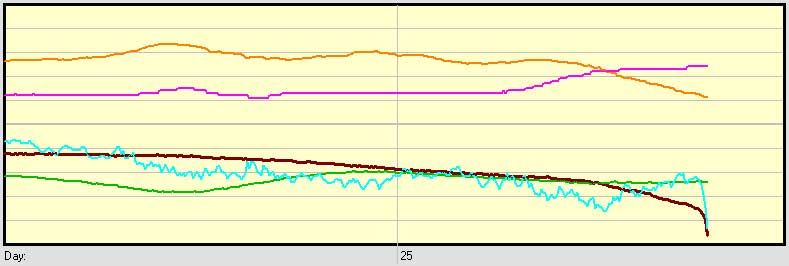

A Broken SuspensionOn February 22 of 2011 the clock started acting odd. Around 3 PM (Hour: 15) the rate started to decline unusually quickly.

This continued, and accelerated, for several days. The amplitude (light blue line) also declined. This means the pendulum was losing power.

Finally, on February 25, the clock stopped completely.

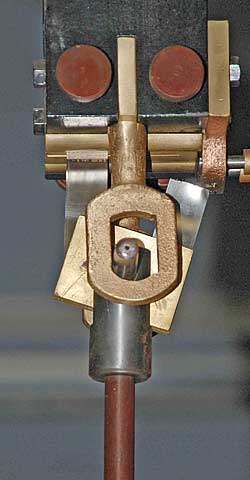

When we were able to examine the clock, we found that the suspension spring, which supports the 170 pound pendulum, had broken. In the picture to the right, notice the horizontal metal pin inside an opening in the brass support. If both leaves of the suspension spring had broken, this pin would be captured by the brass casting and prevent the 170 pound bob from falling to the floor.

Mostyn fabricated a new suspension assembly and we hung it the same day to get the clock running in less than 24 hours. Click here to see how quickly Mostyn and I were able to install the new suspension (QuickTime required). We start by examining the new suspension, fitting it into the clock, removing the temporary support from under the bob, aligning the optical sensor for MicroSet under the bob, and restarting the pendulum. Mostyn resets the four dials while I adjust the pendulum amplitude to the proper range with MicroSet and the computer. We then adjust the rate with MicroSet and the computer, clean up, and head out. The clock room was a mess because we were still in the middle of construction of the Bisno Schall Clock Gallery.

|